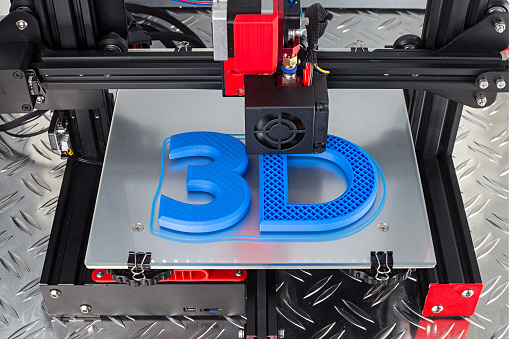

3D printers are the future of manufacturing. They’re becoming better and better each day. You can use them to create anything you’d like: cases for your smartphone or tablet (or even furniture), figurines that will be perfect as gifts one day when kids get older and desire their customized toy versions of any characters from pop culture that we happen to see at any given time while growing up. They can even make musical instruments. The possibilities are limitless with these devices; prior to attempting, there are a few things to know first.

Uses and types of 3D printers

3D printers have been the hottest technology of recent times. They can produce physical objects that are high-quality and clarity. This makes them ideal for designers or architects looking to understand how different materials will appear in their designs. There’s a particular kind of 3D printing machine that may be superior to the rest: FDM (or “Fused Deposition Modeling”), an user-friendly device which works by heating plastics until they are shaped to whatever shape you like This means that you don’t have to worry about needing to play around with different shapes simply pick one of the pre-programmed shapes, such as taco shells or chopper boxes.

Custom-built Printers

It’s a critical decision. Do you have the time to invest enough time? Do you have the knowledge to build? It might be something that interests you. If so, you should think about buying compatible components from someone who has the exact information they need before heading out to stores yourself.

Prices

The 3D printer is an amazing technology that creates three-dimensional objects with either metal or plastic. The costs for these devices vary based on numerous factors , such as the quality, however, they typically are priced between $1000 to over 2000 dollars! If you’re starting out, we suggest that you choose the cheapest option, like the gyro drone which is only $100.

Materials

The 3D printing process is an exciting advancement in manufacturing, allowing for the creation of complicated objects with breath-taking detail. Today, we’ll discuss two types of materials being used at this process: Acrylonitrile Butadiene Styrene and Poly Lactic acid both get extremely soft after heating, but they will harden when cool; but there are some important aspects you need to take into consideration before making a final decision! Not all printers are capable of working using the same material , so make sure you pick the most suitable one for your needs.

Safety

3D printers are amazing tools that can be used to do various purposes, from reproducing human organs to making functional objects. If you have eyes that are sensitive like children and pets, the fumes may make you sick or even cause permanent eye damage. When you consider these points I highly recommend using a high-quality mask while operating one to ensure it’s safe for everyone involved.

Quality

With the aid of a high-quality printer, you can make high-quality printed items. It is important to consider two aspects that affect print speed and resolution. Print resolution is measured by microns. Quality prints are produced using smaller amounts. The speed with which your printer shifts ink affects the speed that an item is eventually printed as well, so ensure that it has sufficient power before starting any projects big or small. It’s a first line machine for your tiny moments.

For more information, click high-temperature 3D printer