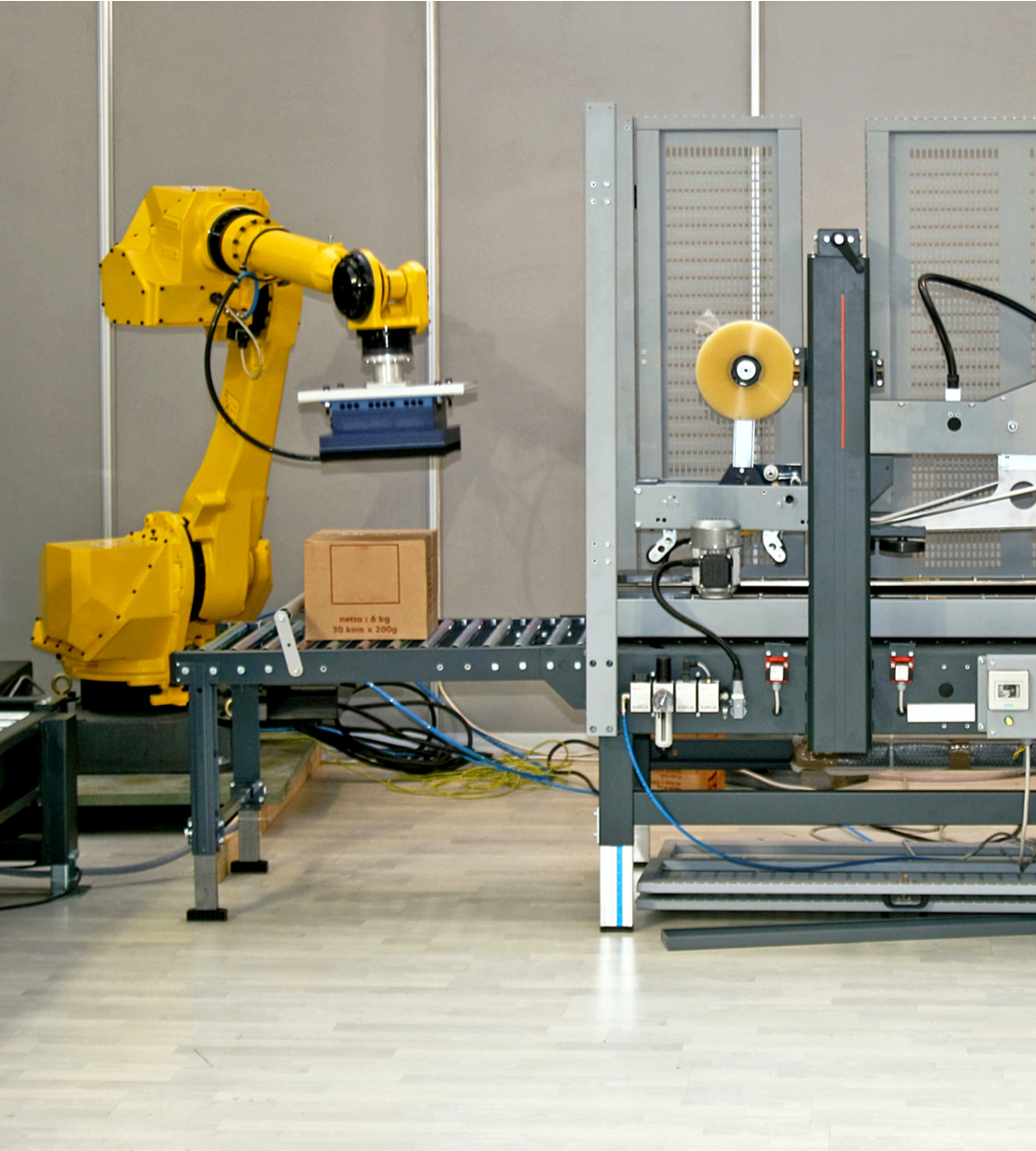

In the field of automation in the industrial sector, the fusion of robotic arms has become an transforming force, altering the landscape of manufacturing and manufacturing processes. Robotic arms, also known as Arm robots industrial, are today essential tools that offer unparalleled precision, safety, and efficiency across many industries. This article explores the capabilities of robotic arms. They also discuss their impact on the modern business environment and the advancement in industrial automation.

Robotic arms or robot arms are a range of mechanical devices which mimic the capabilities and endurance of hands. Automated solutions are employed extensively in fields such as manufacturing electronics and automotive. Pharmaceutical companies also make use of these devices due to their precision. Robotic arms can be programmed to perform tasks. arms allows for seamless integration into a variety of production environments. They offer flexible motion as well as the flexibility to accommodate a variety of operational requirements.

The robotic arm, which is the core of the modern world of automation, has a complicated joint system that rotate and perform linear displacements. This enables robotic arm to navigate complex spatial configurations and manipulate objects with meticulous focus on the smallest of details while also ensuring maximum safety for humans. Robotic arms have become a necessity to the industrial sector which allows them to simplify manufacturing processes and improve operational efficiency.

The usage of end-effectors by robotic arms that are functional equivalent of human hands is one of the most distinct features of robotic arms. The end effectors are usually made for specific functions and play a crucial aspect in determining what robot arms can do. From lifting and gripping large loads, to assembly of intricate parts, robot hands that are equipped with specific end effectors enable robotic arms to execute many different tasks with incredible precision and reliability.

The integration of robotic arms into industrial automation has created a new era in productivity and technological innovation. Utilizing the capabilities of robotic arms, businesses are empowered to streamline their processes for manufacturing, eliminate errors made by humans, and boost the overall quality of their products. The seamless integration of robotic arms and automated systems has led to significant improvements in operational efficiency. Businesses are now able to respond to increasing demands with unprecedented velocity and speed. Click here Robotic Arm

The impact of robotic arms goes beyond simple automation. It’s about a fundamental redefinition in industrial processes. Industrial robotic arms have not just transformed existing manufacturing workflows but also opened the way to new methods of production. Because of their capability to complete tasks in difficult or dangerous environments robotic arms have boosted security in the workplace while opening up new opportunities for complicated manufacturing processes.

Further, the growth of robotic arm technology has led to the creation of innovative end effectors, tailored to address specific industrial needs. These end-effectors feature advanced gripping and sensory capabilities, and have expanded the range of applications for robotic arms.

As Australia recognizes the benefits of automation through robotic arms businesses have an opportunity to transform their efficiency and competitiveness. The integration of robot arms into industrial workflows have the potential to improve productivity and drive growth. With the focus on efficiency and precision, robotic arms are poised to break new ground in industrial automation, helping firms to achieve unprecedented levels of operational performance.

Conclusion: The integration of robotic industrial arms represents a major advancement in industrial automation. Robotic arms, thanks to their unmatched precision, adaptability and safety capabilities have redefined modern manufacturing. They give businesses an advantage in a market which is growing more competitive. As Australia recognizes the transformational potential of robotic arms companies stand to benefit from increased productivity, operational efficiency, and creativity, underscoring the importance of robotic arms in defining the future of automation in the industrial sector.